SMT Service (Surface-mount technology)

| Surface Mount Technology is a method for constructing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). An electronic device so made is called a "surface-mount device (SMD)". |

||||

| Technical Capabilities | ||||

|

|

|||

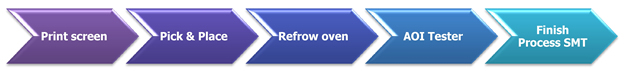

SMT Process

|

||||

Testing Procedures We perform multiple quality assurance procedures before shipping out any board. These include:

|

||||

|

||||